The Impact of FDA Standards on Cannabis Extraction Safety

In 2023, the cannabis industry witnessed a significant shift as the FDA announced they would be creating more stringent regulations on CBD products. This pivotal change marked a new era in the cannabis industry, underlining the federal government’s growing commitment to ensuring product quality and consumer safety in this rapidly expanding market.

As more states continue to legalize recreational and/or medical marijuana, we anticipate that the FDA will extend its regulatory reach to encompass a broader spectrum of cannabis products due to public health considerations, the need for standardized production practices, advancements in extraction technologies, and an increasing emphasis on rigorous scientific research to understand the effects and potential benefits of cannabis.

Existing Standards for Cannabis Extraction

Current federal regulations are narrow, primarily because of marijuana’s Schedule I classification, which makes it federally illegal to use recreationally or medicinally.

As a result of this classification, cannanbis production is extremely limited. The FDA has only issued minor guidance for products containing cannabis or cannabis-derived compounds, such as CBD. These existing regulations focus on ensuring product safety, accurate labeling, and ethical marketing practices. While the FDA has not yet established specific standards for the extraction process, its general food and drug safety standards apply.

The EPA also regulates pesticides and their use on cannabis crops, which indirectly impacts the cannabis extraction process because it affects the quality and safety of the raw material used in the process.

OSHA also has standards for worker safety in cannabis extraction facilities, including regulations on air quality and handling of hazardous materials like solvents.

Lastly, each state (that has approved recreational or medical marijuana) has developed its own frameworks to include specific standards for extraction processes, lab testing, packaging, and labeling. However, these regulations vary—having a federal framework to guide cannabis extraction will be essential for ensuring product consistency and consumer safety.

Potential Regulations

In August 2023, the FDA recommended that the DEA reclassify cannabis as a Schedule III drug, which would significantly change the legal landscape surrounding marijuana.

As a Schedule I drug, cannabis was considered to have no currently accepted medical use. By reclassifying it to Schedule III, marijuana would be considered to have an accepted medical use and, as a consequence, allow it to be dispensed nationwide as a prescription. We will get to what this may mean for the future of cannabis extraction in the following sections.

UL Ratings

One area we predict would change is current safety standards, particularly regarding equipment used in cannabis extraction.

In the future, we can see the federal government requiring UL-rated or -certified equipment.

UL (Underwriters Laboratories) is a global safety certification company that sets rigorous standards for testing and certifying products for safety. When equipment is UL-certified, it has been thoroughly tested and found to meet these specific safety standards. This certification is a hallmark of reliability and is particularly important in industries, such as cannabis extraction, that deal with potentially hazardous materials or processes.

In the context of cannabis extraction, the federal government may require UL-certified equipment as a basic standard to reduce the risk of accidents or malfunctions, ensure product safety, and mitigate liability issues.

ASME Ratings

Similarly, we can also see the federal government requiring extraction facilities to have ASME-certified vessels. The American Society of Mechanical Engineers (ASME) is a globally recognized nonprofit organization that sets engineering and manufacturing standards, with a particular focus on ensuring the safety and reliability of mechanical systems and components.

Pressure vessels are a critical component of many extraction systems, so the FDA may require that extraction facilities purchase ASME-certified pressure vessels to reduce the risk of explosions, leaks, and mechanical failures, ensure uniform safety and quality standards, and improve the legitimacy and trustworthiness of the products being created from the extraction process.

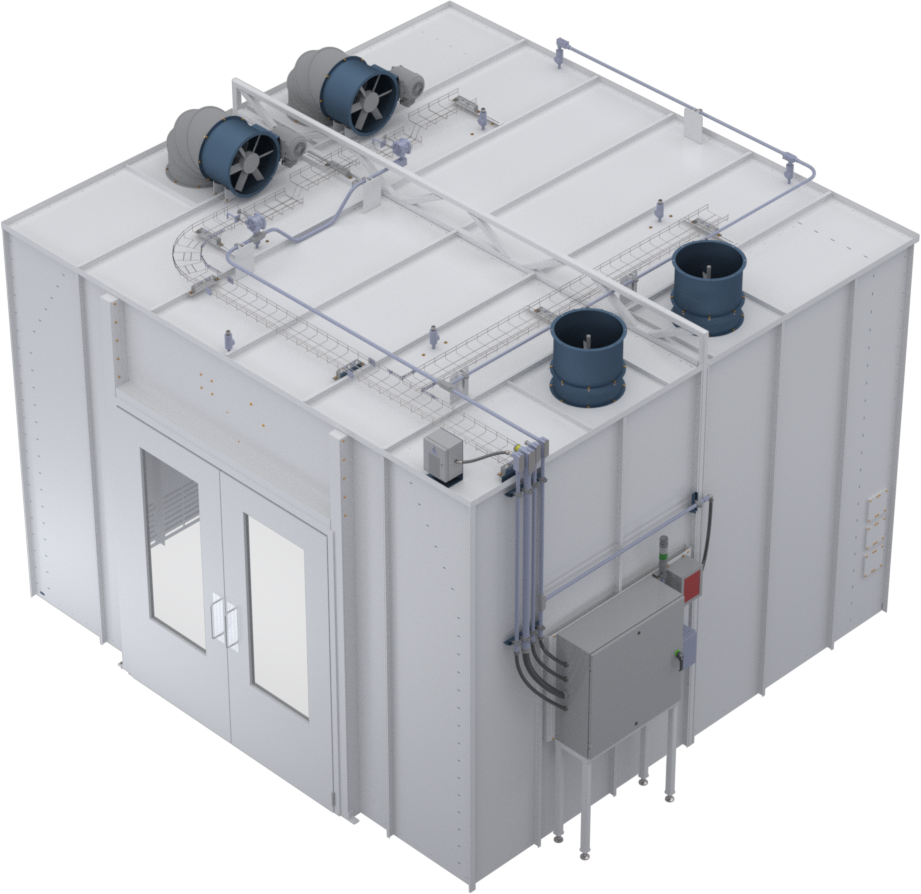

C1D1 & C1D2 Enclosures

The reclassification could also significantly influence the regulation of Class I, Division 1 and Class I, Division 2 enclosures in cannabis extraction facilities.

Currently, regulating C1D1 and C1D2 enclosures primarily falls under local and state jurisdictions. With federal reclassification, there’s potential for more uniform federal standards and stricter enforcement, leading to more consistent safety practices across all states.

Additionally, cannabis extraction facilities could come under closer scrutiny from OSHA, potentially leading to more inspections and compliance requirements. There may also be a push for mandatory certification of C1D1 and C1D2 enclosures.

Safety Controls & Interlocks

Lastly, we believe this reclassification could impact the implementation and regulation of safety controls and interlocks in cannabis extraction facilities to drastically reduce accidents.

Similar to C1D1 and C1D2 enclosures, this would most likely mean stricter safety protocols, including mandatory implementation, and increased regulatory oversight from OSHA and the FDA.

Final Thoughts

We truly believe that compliance will become a significant focus once marijuana is reclassified as a Schedule III drug, and as a result, more and more cannabis companies enter the market.

The FDA’s sole purpose is to ensure the products people consume and/or use are safe and of a consistent quality. This means establishing a framework that all companies within that industry must follow. There’s no reason to believe that cannabis products won’t fall under this same level of scrutiny, especially following marijuana’s potential reclassification.

If you operate in the cannabis industry, this should be a primary concern for you. New federal safety standards might require you to develop and implement rigorous training programs, redesign your facility, invest in new property to incorporate required equipment, and spend extra money on new equipment purchases. Are you ready for this?

Stay Compliant With Help From MACH Technologies

The best way to protect your company’s future is to invest in the best from the beginning.

MACH Technologies is here to help you create safe and compliant automated extraction systems. Our ethanol, hydrocarbon, and solventless extraction systems comply with UL, CE, IECEx, and cGMP and use ASME-certified pressure vessels. When you purchase certified equipment from the beginning, you won’t have to worry about facility redesigns and replacing potentially non-compliant equipment.

As a turnkey provider, we design and engineer our equipment based on your needs, can provide professional recommendations, and even help you implement your system and provide training to your operators.

Please contact us today to learn more about how we can help you now and in the future.