EES Series

Fully Automated and Integrated Solution

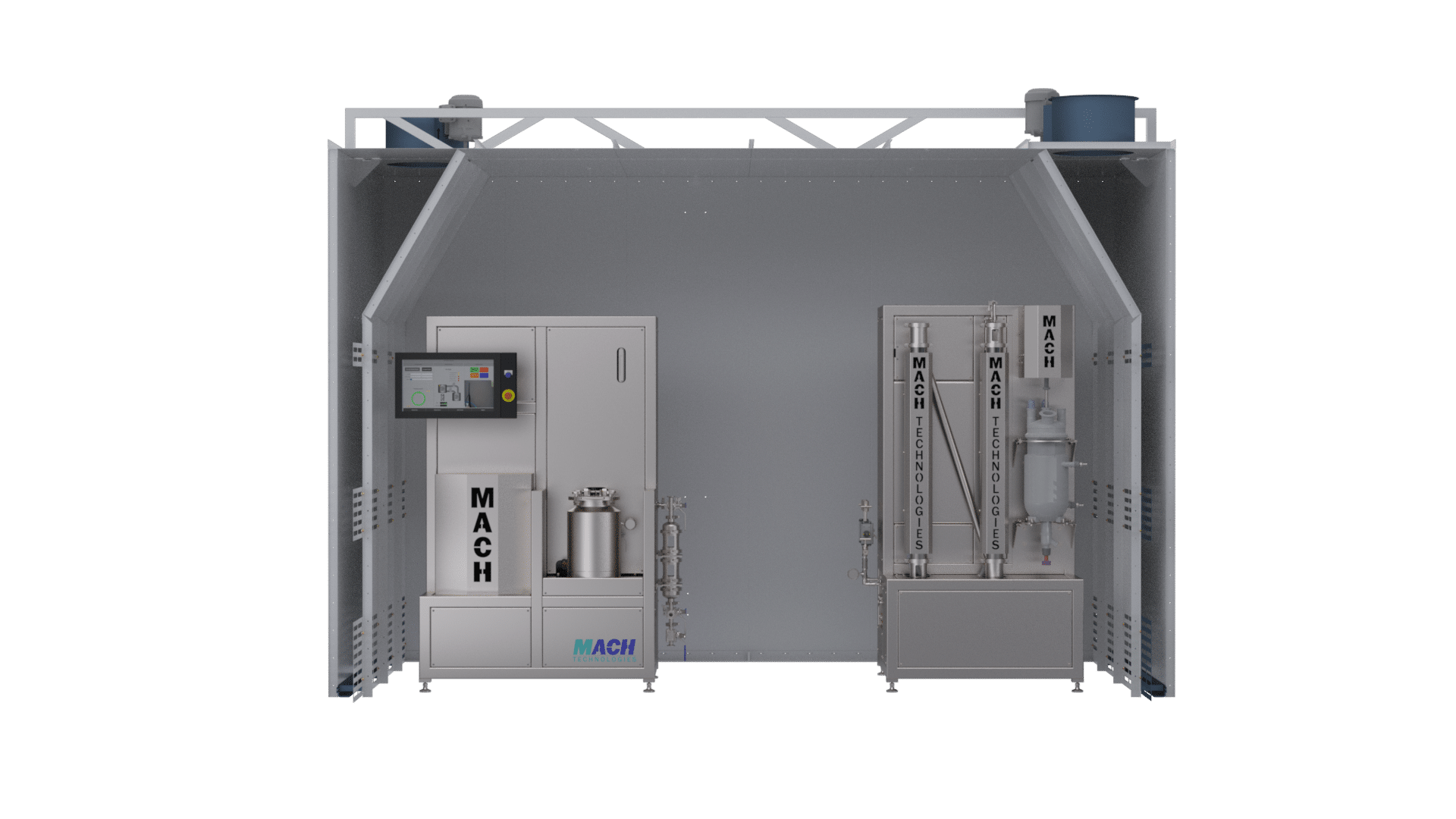

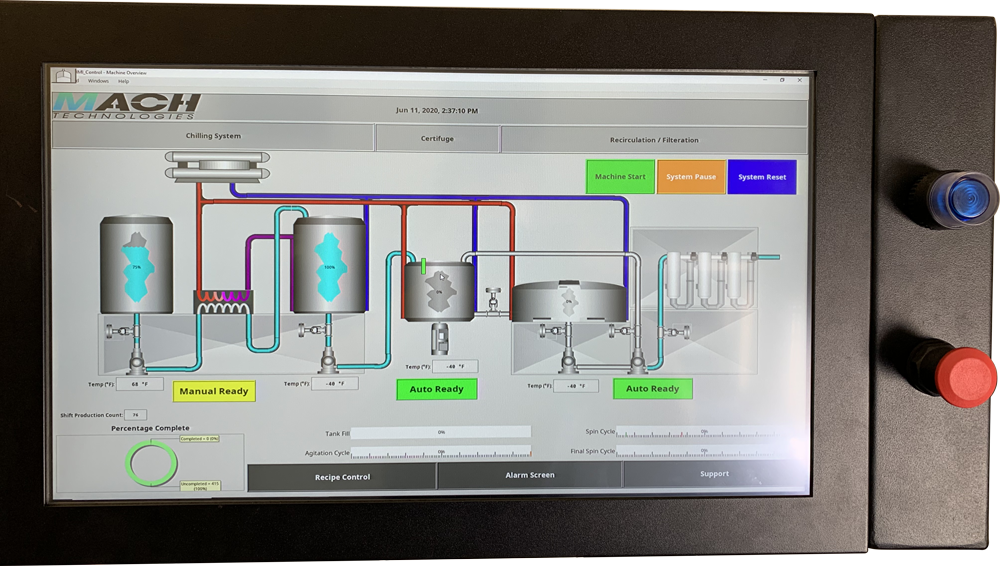

The MACH Technologies EES Series is a complete, PLC controlled, automated cold ethanol extraction system which includes continuous ethanol chilling and pumping, extraction, integrated recirculation, particle filtration, solvent recovery with automated discharge of the recovered ethanol and concentrated oil, and decarboxylation. The entire system is controlled from a single operator interface and provides precision temperature and process controls with automated valving controlled by the MACH proprietary, recipe driven control system

Cryogenic Automated Ethanol Extraction

Automated

Solvent Recovery

Automated Decarboxylation System

Summary

Complete process from ethanol chilling, extraction, recirculation, and filtration is controlled by a single operator interface.

Sizes & Technical Information

EES-X-900 Turnkey

Model: EES-X-900 Turnkey

Capacity: Up to 300 LBS per shift (8 hours), 900 LBS per day

Batch Time: Typically range from 14-18 minutes depending on recipe and SOP's

Includes: Ethanol Storage, Chilling, Extraction, Particle Filtration, Solvent Recovery, Decarboxylation, C1D2 Enclosure, All Ancillary Equipment for a True Turnkey (*Exact equipment depends on final configuration selected by customer)

EES-X-1800 Turnkey

Capacity: Up to 600 LBS per shift (8 hours), 1800 LBS per day

Batch Time: Typically range from 14-20 minutes depending on recipe and SOP's

Includes: Ethanol Storage, Chilling, Extraction, Particle Filtration, Solvent Recovery, Decarboxylation, C1D2 Enclosure, All Ancillary Equipment for a True Turnkey (*Exact equipment depends on final configuration selected by customer)

EES-3000 Turnkey

Capacity: Up to 1000 LBS per shift (8 hours), 3000 LBS per day

Batch Time: Typically range from 15-20 minutes depending on recipe and SOP's

Includes: Ethanol Storage, Chilling, Extraction, Particle Filtration, Solvent Recovery, Decarboxylation, C1D2 Enclosure, All Ancillary Equipment for a True Turnkey (*Exact equipment depends on final configuration selected by customer)

EES-X-144

Capacity: Up to 80 LBS per shift (8 hours)

Batch Cycle Time: Typically between 10-15 minutes, dependent on recipe

Footprint: 92"L x 43"W x 85"H

*Footprint for EES Skid only

SINGLE OPERATOR

The entire skid is controlled through a single operator interface

SUPERIOR ENGINEERING

The entire system was designed by our USA engineering team, who has 40+ years of expertise in chemical, mechanical and controls engineering.

USA MANUFACTURING

This entire system was manufactured in our USA facility, which guarantees the quality.

SAFETY

The system incorporated the latest in safety controls and interlocks, for safe operation

JACKETED VESSEL

The extraction unit has a double jacket for cooling and vacuum insulation, to maximize efficiencies and lower operational costs

C1D2

The machine & components are designed for C1D2 environments

PLUG & PLAY

The machine has plug and play electrical connections for quick installation and trouble-free startup

EASY TO USE

The entire system is controlled via a single operator interface and incorporated automated controls

ON DEMAND SUPPORT

The machine incorporated a remote connection, for on demand technical support from the Python technical team

SPECIALIZED O-RING SEALING SYSTEM

The unit has a cascade o ring sealing system to ensure leak free operation

LOWER OPERATIONAL COST

The machine is designed for efficiencies to reduce the operational costs, such as double tank jackets, insulated piping, motor amperage monitoring system, and electrical cooling

SUPPORT & SPARE PARTS

Python has a dedicated spare parts team, and stocks spare parts for quick, same day shipment

Ready to Partner with Us?

If you are a manufacturer, supplier, referral partner, consultant, etc. and are interested in becoming a part of the MACH network, please fill out the supplier inquiry form below. We look forward to the possibility of working together to provide our customers with the best solutions in the industry. Join is in shaping the future of cannabis extraction technology! Together, we can make a significant impact!